Hydrotest Systems is a true specialist in sheathed fuel injection pipes for diesel engines and are a full-service provider for customers worldwide. Our team of specialists closely cooperate with clients to attain the best solution.

Hydrotest Systems offers a wide range of hydraulic activities. We are specialised in engineering and production of complete systems, including installation, safety and control devices.

As an official service point for Gesipa blind riveting systems, Hydrotest Systems offers pneumatic, battery powered and fully automatic blind riveting machines.

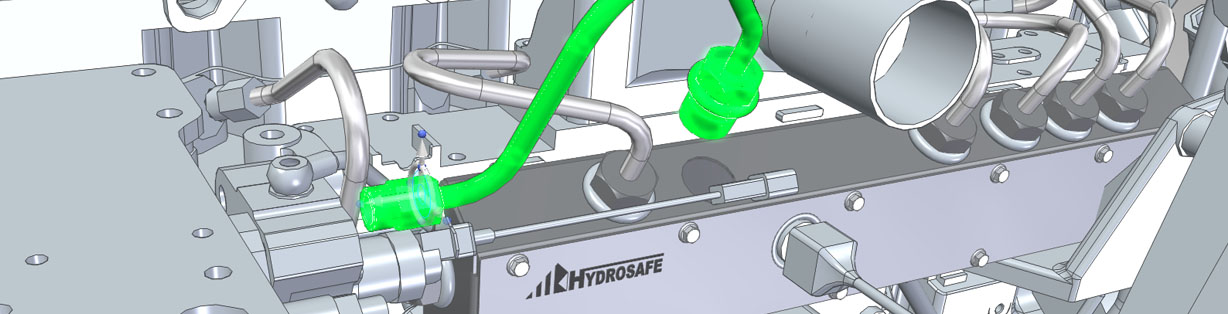

Hydrotest Systems is specialized in the development of sheathed and conventional fuel injection pipes for the marine, power generation and transportation industries. To comply with safety and environmental rules (such as SOLAS) Hydrotest Systems developed the high-end HYDROSAFE® sheathed systems with Lloyd’s approval. How does HYDROSAFE® work? The basics are simple. Leakage from the inner high-pressure pipe is collected by the outer pipe, detected and safely discharged.

In consultation with Lloyds Register of Shipping (LRS), the majority of our fuel lines are developed under Lloyds type approval. In case of special or different fuel lines, Lloyds will perform the inspection on site. Besides our high-quality standard, product fitment and easy assembly are of great importance.

Both standard fuel pipes and specials are manufactured or repaired for OEM, marine, automotive and offshore clients, even also for diesel specialists such as professional tractor pulling teams worldwide. Hydrotest Systems has long term experience in delivering fuel pipes on time and with the highest quality to suit the needs of major engine manufacturers.

We have created our own modern production line to be able to deliver products on short term for multiple engine manufactures and engine types. Fuel lines and supporting spray shields for several common rail systems are also available.

Using the latest state of the art CAD system and measuring systems our engineering team has the ability to produce solutions for new engines and older legacy engine designs. We can import from all popular file formats directly into our CAD system or record data direct from an engine or installation using our measuring equipment in the situation where drawings are not available. Hydrotest Systems can also help to offer SOLAS compliance and spare part support for older engines by either working from archive drawings or reverse engineering existing fuel pipes.

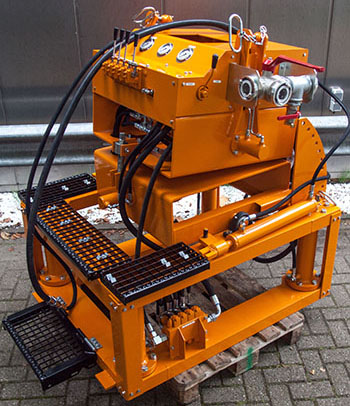

Hydrotest Systems offers a wide range of hydraulic activities. We are specialised in engineering and production of complete systems, including installation, safety and control devices.

High quality components, preventive maintenance as well as use of HYDAC equipment for on-line determination of oil contamination and off-line filtering for years of trouble free output. We can support with your existing maintenance system or set up a complete new maintenance package. We’ll always find the best solution for the toughest engineering challenge.

Hydrolans® is another special project developed by Hydrotest Systems. Hydrolans® is a hydraulic powered device for under ground installation of cables and flexible pipes.

Hydrolans® developed by Hydrotest Systems

Customer satisfaction can be achieved only with excellence, effectiveness and reliability throughout all levels of the organization and in all of its function.

We continuously innovate and develop our services and products to ensure a constant delivery of outstanding quality. To achieve and maintain this goal our whole company operates and maintains a closed loop Quality Management System in accordance with ISO 9001:2015 (download certificate).

Hydrotest uses advanced quality planning tools which include:

We are aware that our customer requests are unique, where there is no second try.

The inspection and test facilities at Hydrotest enables us to provide consistent, high quality and reliable products according customer specification. Our attention to details throughout the entire manufacturing process, from the basic dimensional inspection of the basic machined components, jig testing of all critical position points on bent pipes, to the flushing and final examination of pipe contaminants ensures we can meet the requirements of all modern fuel systems.

We can also offer the following quality services:

We are aware that our customer requests are unique, where there is no second try.

Voel jij je op je gemak als lid van een dynamische organisatie waarbij je je bezighoudt met de dagelijkse gang van zaken rond de productie maar ook technische vraagstukken, dan is dit een geschikte functie voor jou. Wij zoeken een gedreven technisch talent voor versterking voor de productieafdeling van o.a. […]

For everyone who wants to quickly and securely reach his career goal. Hydrotest offers students (MBO/HBO) the opportunity to gain practical experience. At Hydrotest you will be in the middle of the action from the very beginning. Contributing your ideas, helping the team and moving the company forward – this is our motto.

Please feel free to contact us.